Technologies/ Pick and Place / RPP300

RPP300

Reciprocating Pick and Place

The RPP can operate as stand-alone or integrated into existing systems for typical and complex applications such as, collating, blister sealing, inserting or labelling.

High Speed

30,000pph

Placement Accuracy

0.02in

Optional Autoloader

68"Magazine

Low cost of ownership and minimal maintenance

Pack-Smart Reciprocating Pick and Place machinery is ideal for picking almost any size or shape of product from a vertical stack and placing it onto a conveyor, downstream automation module or onto another product. The RPP can operate as stand-alone or integrated into existing systems for typical and complex applications such as, collating, blister sealing, inserting or labelling. Unit comes with standard gravity magazine; however, it can be upgraded to extended capacity and millstream magazines. Digital servo drive is the heart of RPP, it allows for synchronization with most downstream equipment using optical sensors and rotary encores.

REDUCE COST

LOW-COST OWNERSHIP

MAXIMIZE THROUGHPUT

REDUCE COST OF CONSUMABLES

GROW YOUR BUSINESS

HIGH ACCURACY PLACEMENT

WIDE VARIETY OF LABEL TYPES

& SIZES

REDUCE DOWNTIME

MAXIMIZE UPTIME

QUICK CHANGEOVERS

MINIMAL MAINTENANCE

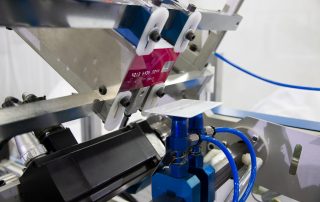

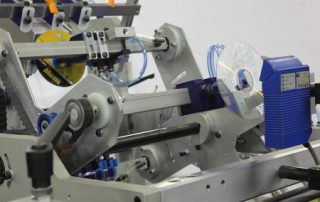

RPP300 in Action

Reciprocating Pick & Place

Reciprocating Pick and Place Feeders

Performance

- Maintenance free brushless servo drive with high speed and acceleration

- Vacuum suction with pneumatically actuated blow off

- 6 arm rotary feeder with adjustable spring loaded suction cups

- Low backlash planetery drive system

Efficiency

- Autoloader module for extended magazine capacity and automatic product in-feed*

- Twist lock handles for adjustable module position

- Adjustable magazine mounting bracket with position indicators

- Tool less adjustable product clips

- Touch screen human-machine interface

Reliability

- Pneumatic seperators prevent double product pickup

- Oil free, air cooled vacuum pumps

- Anodized aluminum build

- Polycarbonate safety hood

Compatibility

- Modify product pick up and drop off points with adjustable cam

- Mobile stands*

- Optical sensor kit*

- Rotary encoder kit for on the fly speed synchronization*

* Optional feature

Performance

- Max. Speed

- 30,000 pph

- Placement Accuracy

- TBD

Product

- Min. Product Size (LxW)

- 32 x 32 mm (1.25″ x 1.25″)

- Max. Product Size (LxW)

- 279 x 229 mm (11″ x 9″)

- Min. Product Thickness

- 0.05 mm (0.02″)

- Max. Product Thickness

- 6 mm (.25″)

Physical

- Magazine Size

- TBD

- Number of arms

- 6

- Arm width

- 305 mm (12″)

- Unit Length

- 864 mm (34″)

- Unit Width

- 559 mm (22″)

- Pick & Place Diameter

- 660 mm (26″)