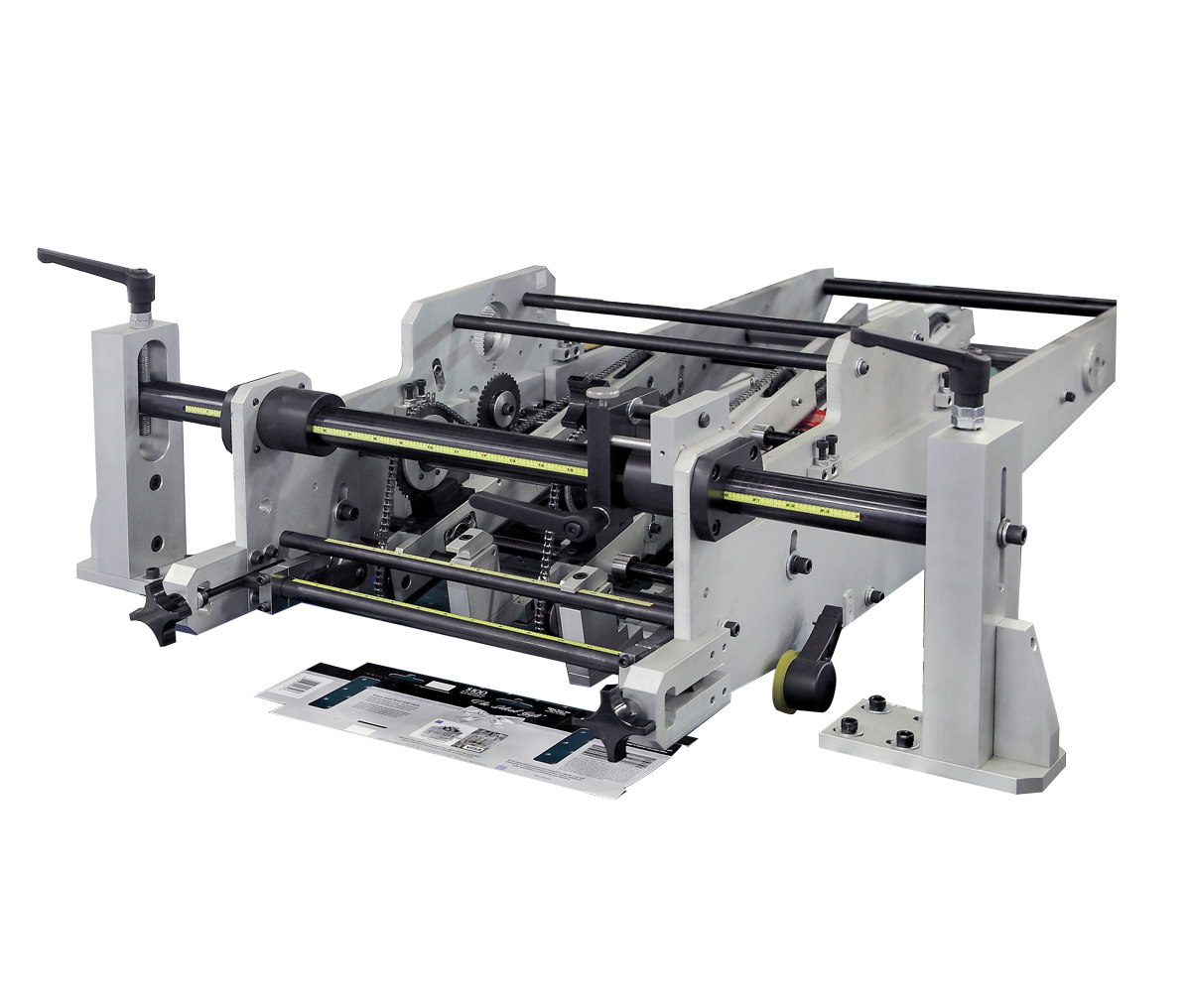

Technologies/ High-Accuracy Affixing & Joining / ABM700

ABM700

Automatic Bottom Alignment Module

Register and index products to place on to carrier for high accuracy affixing

Application Speed

30,000pph

Placement Accuracy

1/32in

Max Product Gauge

12mm

Low cost of ownership and minimal maintenance

The ABM is a chain-driven section that is mounted below the Rotary Placer and transfers items onto the carrier documents more accurately than the Rotary Placer alone. It is not suitable for flow-wrapped items. It can be moved in and out of line when not required for certain applications. This module also allows for the placement of unique products on the same carrier with the possibility of offsetting placement position.

REDUCE COST

LOW-COST OWNERSHIP

MAXIMIZE THROUGHPUT

REDUCE COST OF CONSUMABLES

GROW YOUR BUSINESS

HIGH ACCURACY PLACEMENT

WIDE VARIETY OF LABEL TYPES

& SIZES

REDUCE DOWNTIME

MAXIMIZE UPTIME

QUICK CHANGEOVERS

MINIMAL MAINTENANCE

ABM700 In Action

RP with ABM

RP with ABM

Card Affixing

Performance

- High performance brushless servo motor to drive chain conveyor

- Indexing chain conveyor with paddles for accurate product alignment

- Optical sensors with LED indicators for detecting product position, registration for product mating, and jam detection

- Multiple chain conveyors to handle simultaneous parallel product streams *

- Swivel lock handles to adjust height and lateral position of module

- Dial gauge for precise microadjustment of lateral module position up to 0.001″

- Adjust chain conveyor and side guides to accommodate for various product sizes and feed positions

- Missing product detection for signalling to downstream equipment *

- Nip rollers with adjustable extension *

- Vacuum suction to secure product onto chain conveyor

- All chains are powered by single drive through gears and timing belts

- Heavy duty anodized aluminum frame

- Clear polycarbonate cover to protect against pinch points while mantaining view of product feed

- Low operating temperature and low friction allows for long service life in high speed operation and reduced energy consumption. Pre-lubricated so lubrication is not required.

- Touchscreen user interface screen for machine control

- Quadrature encoders to synchronize lug conveyor and vacuum conveyor speeds *

- Programmable gear ratios without mechanical linkages

- Enables mounting of module to alternate locations *

Performance

- Placement Accuracy (+/- mm)

- 1/32″

- Max. Speed (pph)

- 30,000

Physical

- Min. Prod. Length (mm)

- 25

- Max. Prod. Length (mm)

- 228

- Min. Prod. Width. (mm)

- 25

- Max. Prod. Width (mm)

- 300

- Min. Prod. Thickness (mm)

- –

- Max. Prod. Thickness (mm)

- –

- Magazine/Roll Size (mm)

- –

- Min Product Gauge (mm)

- –

- Max Product Gauge (mm)

- 12

- Physical Length (mm)

- –

- Physical Width (mm)

- –

- Physical Height (mm)

- –

- Protection Rating

- –

Electrical

- Motor Size (Hp)

- –

- Standard Voltage (V)

- 220

- Power Consumption (A)

- 20

- No. of Phases

- 1

- Line Frequency (Hz)

- 60 Hz

- Air Pressure (PSI)

- 60 minimum

- Air Consumption (cfm)

- –

- Unit Weight (kg)

- –

Operating Conditions

- Ambient Temp. (°C)

- –

- Relative Humidity

- –